- Menu

- Home

- Services

- » Crane Refurbishment

- » Crane Surveys

- » DIEPA Wire Ropes

- » Expert Witness

- » Fabrications

- » Hydraulic Gantry Systems

- » Mobile Brake Efficiency

- » Nuclear Cameras

- » Nuclear Cask Transporters

- » High Integrity Nuclear Cranes

- » Spare Parts

- » TII Group

- Agency List

- Equipment for Sale

- Case Studies

- » Nuclear Cranes

- » Heavy Crane Industry

- » Expert Witness

- » Gantry Systems

- » Nuclear Cameras

- » Construction

- » Technical Demolitions

- Client List

- Contact

Nuclear Cameras

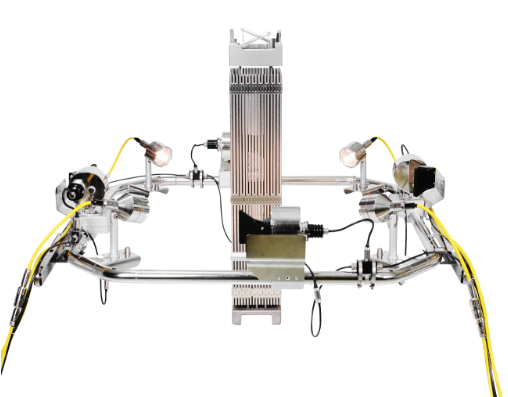

Nuclear Cameras by Ahlberg – Sweden (6c)

The name Ahlberg is recognised as being the forefront in the development of advanced colour camera and cctv systems for nuclear surveillance and inspection technology.

Ahlberg only supply the nuclear industry and therefore make specially designed products for nuclear special applications in new build and decommissioning projects. They have supplied systems worldwide – to nuclear installations & plants from USA, Europe and Asia. They have recently become part of Brokk Sweden.

Claxton International and Ahlberg are already know to end clients such as Magnox and Sellafield and are also involved with a number of decommissioning projects with many of the larger contractors and consortiums.

Technology included in some of these projects include:

· 4 – Face Fuel Inspection Systems is installed above the upender on either the containment or the spent fuel side. It records a video of all four sides of each fuel assembly in colour.

· BWR Mast Cameras : Designed for permanent installation on a BWR refuelling machine mast. It surveys all fuel handling movements by using a remotely controlled adjustable angle mirror.

· Underwater Lighting : Robust radiation tolerant high-power underwater pond lighting for illumination of the reactor and fuel pools.

· Special LED lighting units for illumination operation in air/argon to supplement integral camera lighting in such as caves and silos.

· CCTV : Radiation hardened CCTV cameras that are designed for areas with high levels of gamma and neutron radiation. The cameras also feature an internal cooling system in order to handle the high temperatures in the containment/drywell.

· MRAD Cameras : State of the art regarding image quality, radiation tolerance and colour reproduction. Specially designed for areas of reactor vessels and internal parts in reactors of any type. The colour MRAD L is also ideal for fuel inspections.

· XRAD-PTZ Cameras : High resolution pan and tilt camera with perfect colour reproduction. It is designed to work in high radiation areas during core and baffle plate inspection, including fuel and rod inspection. They were used extensively in Fukushima in difficult circumstances and produced some remarkable results in quality of pictures and data.

Call +44 (0)1244 661000 or email info@claxtoninternational.co.uk

Head Office Claxton International . Sarankot House . Gell Farm . Kinnerton Road . Lower Kinnerton . Chester . CH4 9AE . United Kingdom